The UK's most hyped chef knife is forged in Somerset [WFJ #92]

How story, provenance, and a pleasure for cooking is central to a rekindling appreciation for craftsmanship

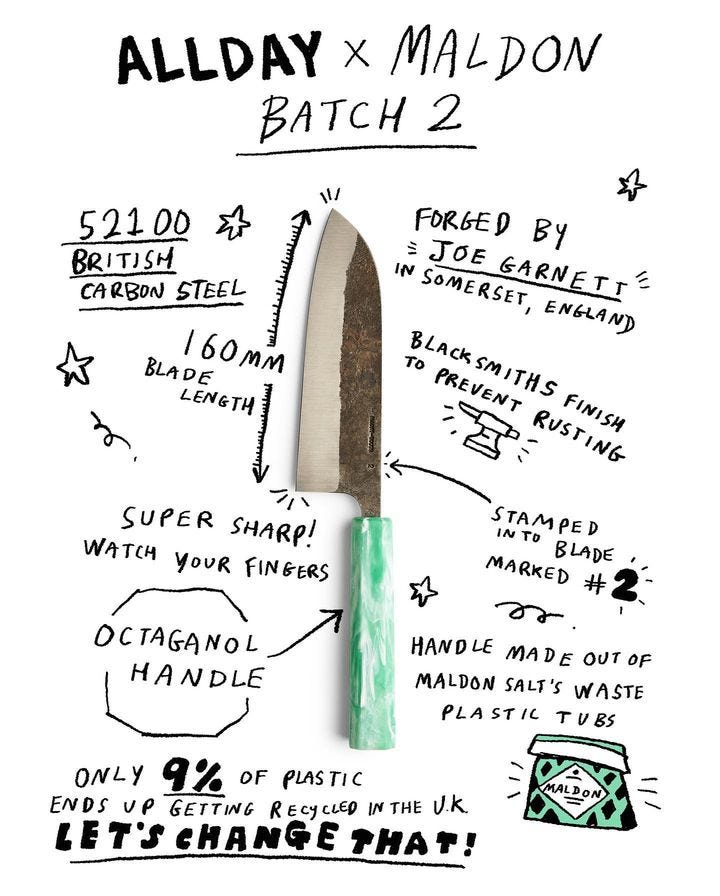

The first time Allday Goods put their chef knives up for sale, they sold out in 78 seconds. Why exactly is anyone’s guess, though it may have had something to do with the alluringly-patterned handles (melted down from waste plastic plant pots), or the striking pationations on the blades themselves.

A project born in lockdown to create an eye-catching ‘high-quality knife that wouldn’t break the bank’, Allday Goods started out contracting blades from a fourth-generation blacksmith in Sakai, Japan – one of the most reputable knife-making regions in the world. Eventually, Allday Goods wanted at least in part to localise production while making use of British steel, the historied thing it is. And so, in a roundabout sort of way, Allday wound up having their knives made somewhere far less known for its smithing culture: Somerset. Specifically, the Hinton Park Estate, just west of Crewkerne.

There at Thorn Wood Forge, Joe Garnett was making knives and axes pretty much entirely for the forge’s own shop and its bespoke clients. That is, until Joe got a call from Allday Goods to make 60 santoku knives a month. As experienced knife-makers tend to do, he chose to use Sheffield 52100 carbon steel – a type of steel that, ultimately, chops, slices, and dices much more competently than your average stainless steel blade (albeit with a bit more TLC from its user). Unlike the smoothness and monocolour of a stainless knife, one from carbon steel also offers texture and character. “Each [Allday Goods] knife is extremely similar,” Joe tells the WFJ. “But at the same time they're all different, because they each have a different pattern of hammer strikes. Each knife has a personality.”

When they’re shipped to Allday Goods’ workshop in Dalston, Joe’s knives are finished with what has become Allday’s trademark. That is, plastic gathered from a variety of sources – including Margate beach, Maldon salt tubs, or Dusty Knuckle bakery’s bin next door – melted down and refashioned into a knife handle.

When Thorn Wood makes its knives entirely in house however, it’s here where the Somerset landscape comes in handy. “We'll go out and find a burr or a knotty piece of wood, usually something that's already been felled,” Joe says. “When you cut through that it produces beautiful patterns. We'll then cut it into blocks, dry it out completely, and stabilise it in resin so it doesn't react to moisture changes in the air so much. Then we use it on the knife handle.”

Other than of course its importance when cooking (in my experience at least, a cheap, blunt, mass-produced knife usually begets a miserable time preparing food), there’s a reason people prize a good knife beyond its aesthetics. Status, perhaps, but often embedded in these decisions is a desire to preserve traditional craftsmanship, and the communities they support or rely on.

Perhaps that’s part of why Britain’s market for handmade goods continues to rise (supposedly at a rate of 4.5% each year), and why small brands making kitchen implements from scratch, and with a strong narrative on craftsmanship – like Netherton Foundry and their spun iron frying pans – have, quite tangibly, gradually become more recognised in recent years.

Understanding the workings at the opposite end of the spectrum has something to do with it too. Knives off the shelf of somewhere like Wilko, Ikea, or Sainsbury’s are, in their production, mechanically stamped out of what is essentially a big sheet of stainless steel – as Joe says, almost literally “cookie-cutter” style.

Consequently, producing or purchasing a kitchen tool in this manner (quite emblematic of the Sam Vines Boots theory) is, seemingly, where romanticism goes to die. “But there’s a time and a place for that,” Joe says, “as not everyone’s able to afford what we make. You can buy a pair of knives from Ikea for three quid, or you can buy one from us for £250, but they do last multiple lifetimes – you'll pass it down to your grandkids.”

These are the kinds of stories we might attribute to objects, whether it’s a more affordable Allday Goods knife that asks questions of our broken, disposable relationship with plastic, or one made to order that says something about rural family heritage – as is the case of a not uncommon request Thorn Wood Forge receives in turning old shotguns (ornate as they often are, with their damascus barrels and engraved side plates) into kitchen knives. “We're using the barrels as cladding for the blade,” says Joe, “and the stock for the handle. What that means is if you've got grandad's old gun, the barrels too thin to shoot anymore, it's got to sit in a cabinet or get scrapped. But if we can take that and turn it into a reusable tool, I think that's amazing.”

As is so often true of food, modern conveniences have made it easy to forget – or ignore – what goes into a product before mass production became so dominant. As is also so often true of food, recognising what originates from the land and the locality, and the skills with which to conjure it, does not make it unlikely for those paradigms to shatter.

Maybe those likenesses are obvious. Or maybe not as much as they should be: “People can spend a lot of time thinking about the ingredients they're going to cook with,” Joe says. “But they then think very little about using a very cheap plastic chopping board with a very cheap knife. We think sourcing locally should continue into every aspect of life – where possible.”

Read next:

The Somerset potters making plates for the area's favourite restaurants [WFJ #79]

Restaurants – particularly many of the good ones – want to tell you a story. There are times, like in their branding, when that’s more obvious. There are times, like in what producers they source from, or how the servers address you, it’s a little less so.

![The Somerset potters making plates for the area's favourite restaurants [WFJ #79]](https://substackcdn.com/image/fetch/$s_!blve!,w_280,h_280,c_fill,f_auto,q_auto:good,fl_progressive:steep,g_auto/https%3A%2F%2Fsubstack-post-media.s3.amazonaws.com%2Fpublic%2Fimages%2Fcd8ec54c-b973-459b-aa3b-4b0d360ceee2_1091x748.jpeg)